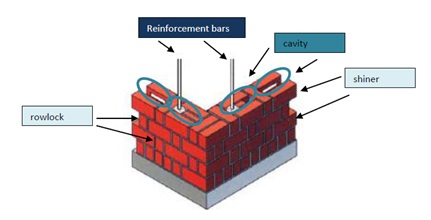

A “Rat-Trap Bond” is a type of wall brick masonry bond in which bricks are laid on edge (i.e. the height of each course in case of a brick size 230x110x75 mm, will be 110 mm plus mortar thickness) such that the shinner and rowlock are visible on the face of masonry as shown below.

This gives the wall with an internal cavity bridged by the rowlock. This is the major reason where virgin materials like brick clay and cement can be considerably saved. This adds this technology to the list of Green building technologies and sustainability for an appropriate option as against conventional solid brick wall masonry.

This cavity adds an added advantage as it adds a Green building feature of help maintain improved thermal comfort and keep the interiors colder than outside and vice versa.

The Rat trap bond construction is a modular type of masonry construction. Due care must be taken while designing the wall lengths and heights for a structure. The openings and wall dimensions to be in multiples of the module. Also the course below sill and lintel to be a solid course by placing bricks on edge. The masonry on the sides of the openings also to be solid as will help in fixing of the opening frame.

B. MATERIALS SELECTION AS PER NEED AND DESIGN

Bricks

- As far as possible, use of fired clay bricks should be checked with alternative bricks i.e. fly ash bricks, bricks from construction waste etc as firing of bricks is in general highly energy consuming and air polluting.

- These alternate bricks provide better strength and durability than fired clay bricks and finishing cost of your wall can be saved with a better quality and aesthetically soothing environment in the interiors.

Mortar:

- Lime should be explored as a material for mortar as it is locally available in many parts of the country and helps reduce the consumption of cement.

- Lime as a binding material along with fly ash can result in to make lime pozzolona mortar which saves on your cost of cement. It also adds another Green building feature, use of industrial waste (i.e. flyash) as a raw material for your construction.

C. ADVANTAGES OF USING RAT TRAP BOND TECHNOLOGY

- By adopting this method of masonry, you can save on approx. 20-35% less bricks and 30-50% less mortar; also this reduces the cost of a 9 inch wall by 20-30 % and productivity of work enhances.

- For 1 m3 of Rat trap bond, 470 bricks are required compared to conventional brick wall where a total of 550 bricks are required.

- Rat trap bond wall is a cavity wall construction with added advantage of thermal comfort. The interiors remain cooler in summer and warmer in winters.

- Rat-trap bond when kept exposed, create aesthetically pleasing wall surface and cost of plastering and painting also may be avoided.

- Rat trap bond can be used for load bearing as well as thick partition walls.

- All works such as pillars, sill bands, window and tie beams can be concealed.

- The walls have approx. 20% less dead weight and hence the foundations and other supporting structural members can suitably be designed, this gives an added advantage of cost saving for foundation.

- Service’s installations should be planned during the masonry construction if not exposed.

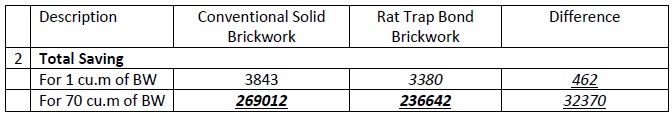

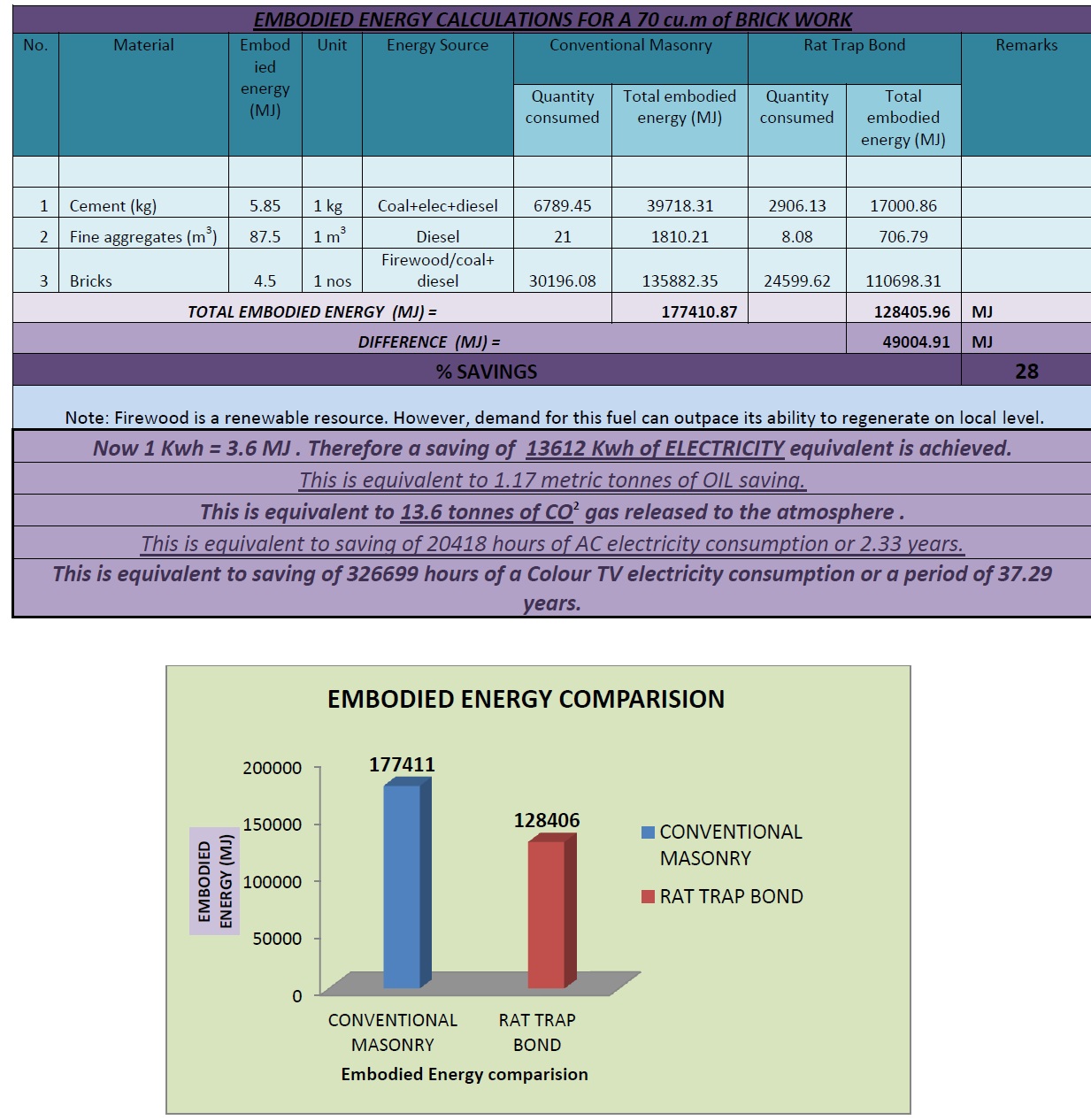

- Virgin materials such as bricks, cement and steel can be considerably saved upon by adopting this technology. It will also help reduce the Embodied Energy of virgin materials and save the production of Green House Gases into the atmosphere.

- In case for more structural safety, reinforcement bars can be inserted through the cavity till the foundation.

D. COST SAVINGS

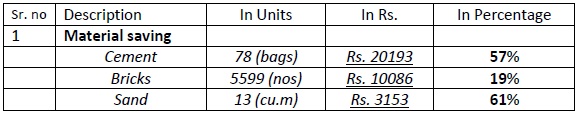

Material saving per m3 : Rat trap bond vs. Conventional Brickwork.

- 1.11 bags (57% saving) = Rs 288/ m3 saving in cement cost.

- 80 nos. of bricks (20% saving) = Rs 576 saving in brick cost.

- 0.18 m3 less sand (61% saving) = Rs 13/ m3 saving.

Summarising the material cost, an approximate saving of Rs. 478 (20% saving) is achieved per m3 of Rat trap bond brickwork compared to conventional solid BW.

- Assume building a house with 100 sq m on each floor, and the periphery walls are made of Rat trap bond instead of conventional bond, the savings in materials cost and total brickwork cost that can be achieved are listed below: